Email us at goldberg@pinfire.de

Nanoparticles - Monodisperse Silica Particles (Microspheres & Nanospheres)

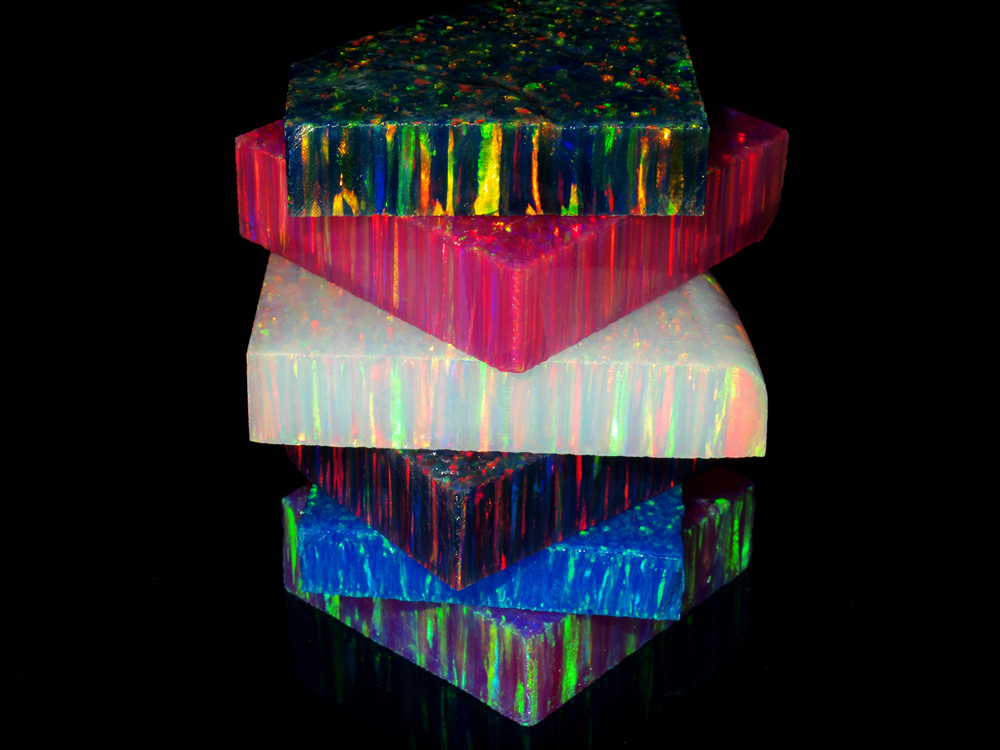

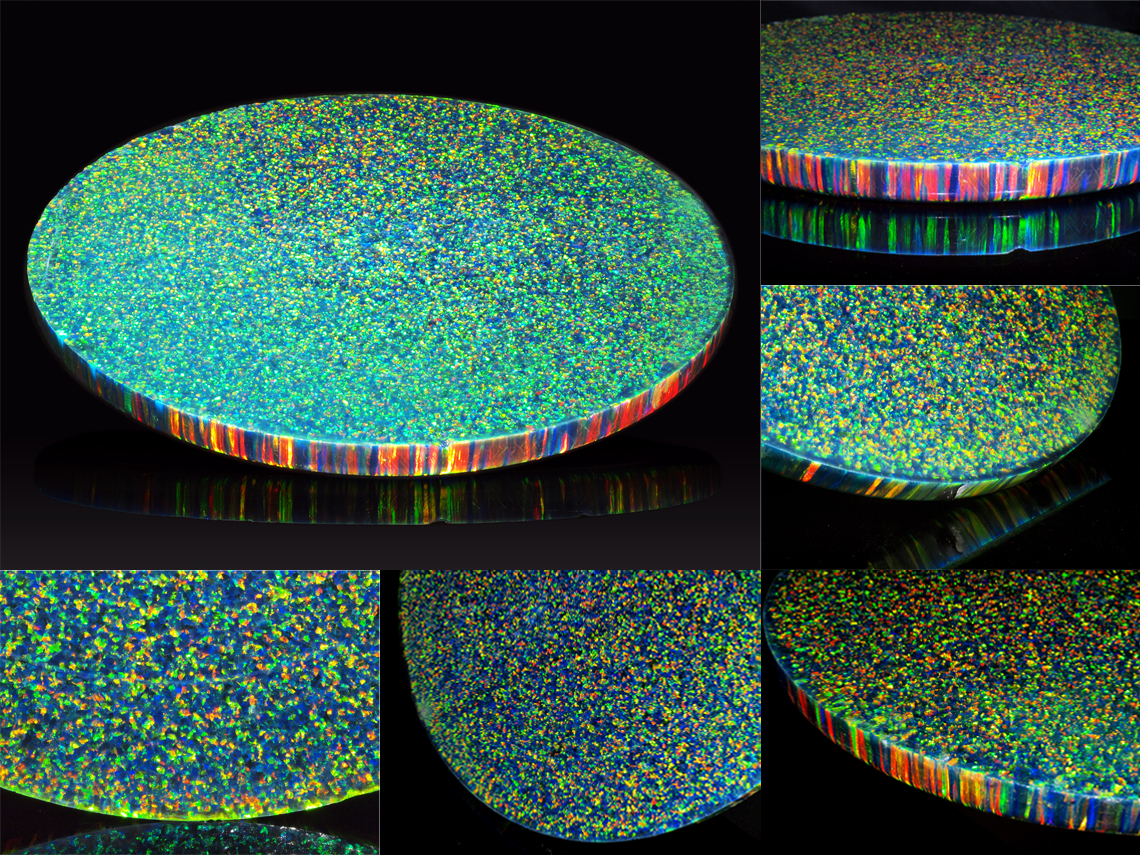

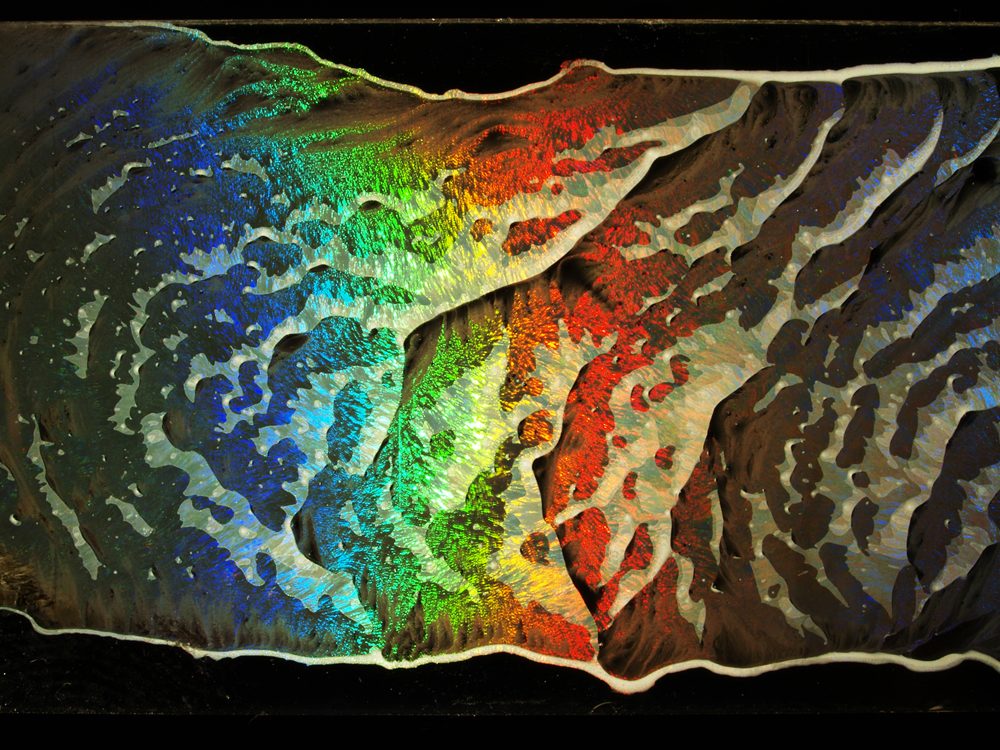

Synthetic Opal - Black Opal, White Opal, Crystal Opal & Fire Opal

Preparation of Coarse and Fine Crystalline Opals with Different Patterns

Synthetic Opal Online Shop: Synthetic Opal & Lab Created Opal

Steps To Grow Synthetic Opals With A Brilliant Play-of-Color

Black Opal, White Opal, Crystal Opal & Fire Opal. Synthetic Opal Manufacture.

Synthetic Opal - Small sliced opals in different color combinations (top) and the largest round slab with a diameter of 22 cm (bottom)

Our Manufacturing Process of Synthetic Opal and Imitation Opal.

Synthetic Opal Manufacture.- Step 1: Preparation of monodisperse silica particles

Our advanced technology allows us to produce highly monodisperse spherical silica particles. Special features of these particles are an extremely narrow size distribution with sizes comparable to the wavelength of visible light. These particles are an essential prerequisite to obtain a synthetic opal with brilliant colors. - Step 2: Self-assembly into a crystalline colloidal array

In this step colloidal crystals are formed by gravitational sedimentation of monodisperse silica particles. This process, also known as heterogeneous crystallization, leads to a close packed arrangement of silica particles with angle dependent bragg diffraction colors, the well-known "play-of-color" or "fire" of synthetic opals. - Step 3: Drying

After controlled drying, a polycrystalline porous synthetic opal is obtained, which is comparable to natural occurring hydrophane opals. - Step 4: Impregnation

The porous synthetic opal is now impregnated with resin to achieve high toughness and strength. With carefully selected resins and monodisperse silica particles in certain sizes, we are now able to offer synthetic opals in high quality with different body colors and a play-of-color in red, orange or green.

Our synthetic opals are manufactured in 4 main stages:

Synthetic Opal - Preparation of Non-Porous Spherical Monodisperse Silica Nanoparticles

Our silica particles are manufactured in-house by utilizing our proprietary process. For the manufacture of synthetic opal we produce particles in a size range of 250-320 nm. It is crucial that the particles are spherical and highly monodisperse. If the particles are oddly shaped and/or polydisperse no or only dull colors can be observed. Therefore, every single batch of particles is carefully monitored to maintain the necessary high-quality level. (Monodisperse Silica Nanoparticles, 50 ml Sample)

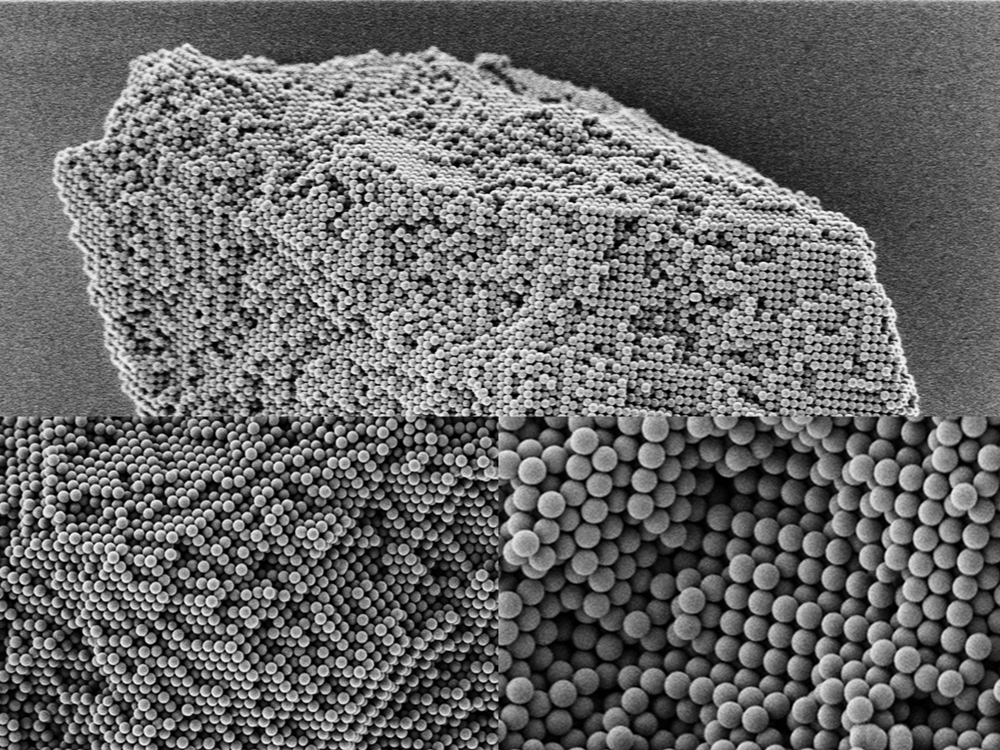

Scanning Electron Micrographs Of Silica Particles (3D Ordered, Hexagonal Close-Packed Array)

Monodisperse Spherical Silica Particles (Dried On A Glass Slide)

"Nano Poodle" - Winning Entry of the "Science Photo Contest", Organised by the German Association of Nanotechnology

Monodisperse Silica Particles - Quality Check

Shape and size distribution of monodisperse silica particles can be precisely assessed by using Scanning Electron Microscopy (SEM, Picture above) and Light Scattering Techniques.

A simple way with minimal effort to gain a first impression of the quality is to prepare a diluted particles suspension, which is left to dry on a glass slide. During the drying process the silica particles arrange themselves into close packed layers and (should) show bright Bragg diffraction colors under illumination with white light (Picture top left, macrophotograph).

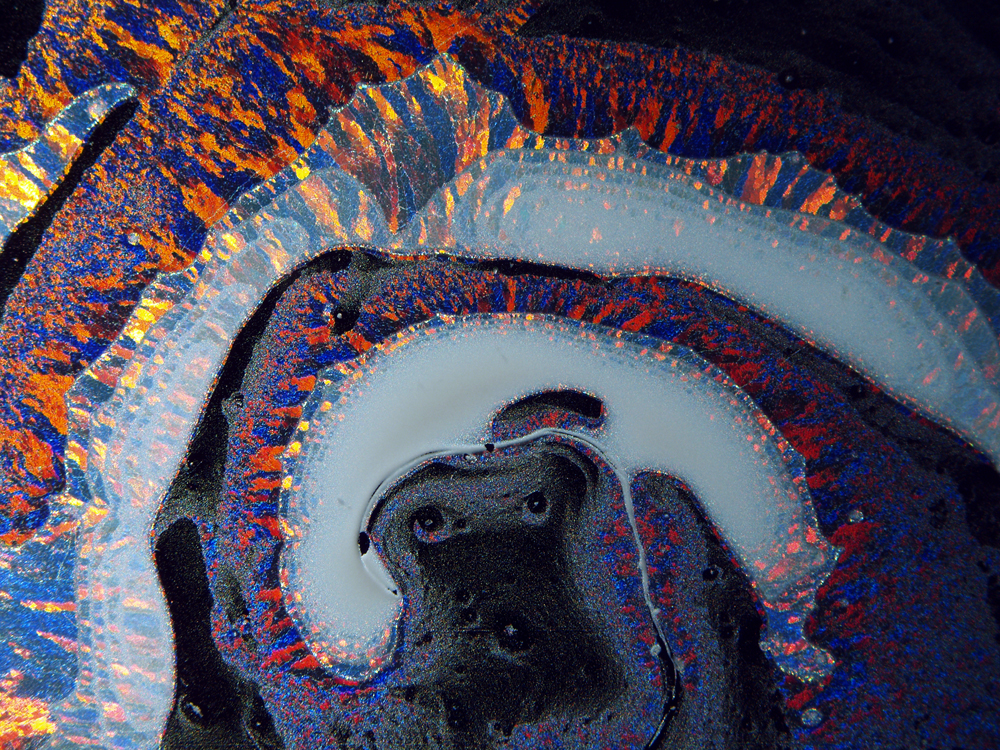

Analyzing opaline layers under a microscope reveals beautiful landscapes. Waves, hills and mountains, seasides, rivers, lakes and many other structures appear. All come in different colors, which can be changed in just a second by varying the viewing/illumination angle. Other images of dried colloidal particles are presented in our "Gallery of Colloidal Crystals"

Synthetic Opal - Colloidal Crystallization.

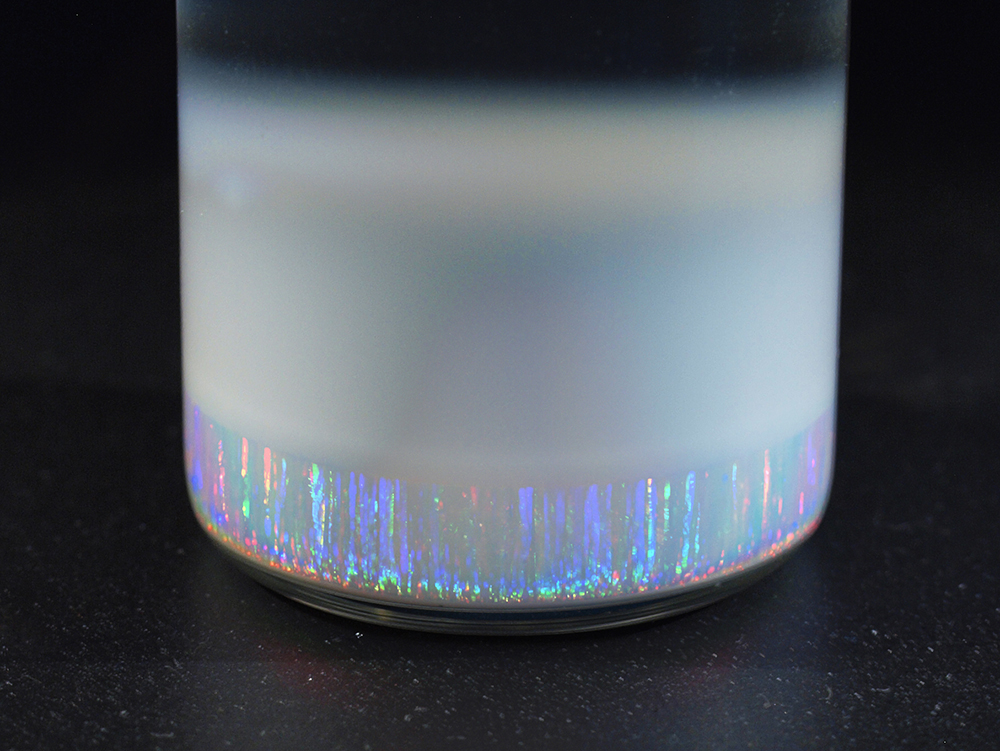

All currently available synthetic opals are produced by sedimentation of monodisperse silica particles under gravity. Without exception!

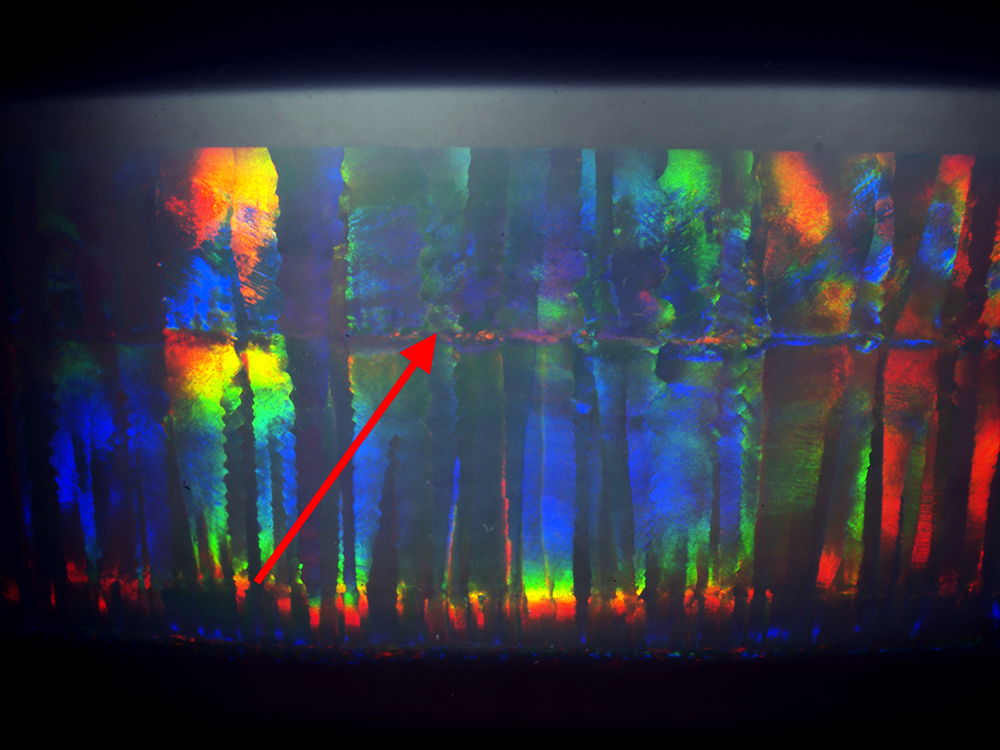

The particles are finely dispersed in water and afterwards left for sedimentation, which is a long, time-consuming process. To avoid defects, this process should take place without any mechanical disturbance. The growth of synthetic opal under sedimentation is a process of hetereogeneous crystallization and starts with the formation of an ordered layer of particles at the bottom of the vessel. With ongoing sedimentation, layers of hexagonal ordered particles stack on top of each other and the final result is a crystalline sediment with the typical striated/columnar pattern parallel to the growth direction. The dimensions of the columns can be varied by changing the concentration of particles - lower concentrations lead to larger columns (and a prolonged sedimentation time).

Sedimenting Monodisperse Silica Particles (Test Tube)

Synthetic Opal - Sediment of Monodisperse Silica Particles. The Arrow Indicates a Narrow Band with Growth Distortions, Caused by Movement.

Synthetic Opal - Crystallization of Colloidal Silica Silica Particles

To observe angle-dependant diffraction colors it is necessary to create a three-dimensional periodic structure with lattice distances comparable to the wave length range of visible light.

The video on the left shows the ordering process of spherical colloidal silica nanoparticles in real time under a microscope.

During the ordering process the particles align themselves into a random hexagonal close packed structure (rhcp).